Anywhere you go, you’ll likely see concrete as part of buildings, homes and other structures. That’s because it’s the most commonly used building material. With that said, it comes at a cost.

The Problems With Concrete

Although concrete has been the most popular building tool for decades, it takes a toll on the environment in a few different ways.

1. Carbon Dioxide

Cement is the biggest ingredient in making concrete, but it involves a certain percentage of greenhouse gas emissions. It adds up to contribute about 8% of the world’s total carbon dioxide (CO2) emissions. The process emits CO2 in two different ways.

First, it requires heating a kiln to high temperatures, which uses energy. Second, in the process of mixing cement into concrete, another transformation takes place — calcination. This is when limestone gets heated, turning it into quicklime.

2. Increase in Production

The world’s population is growing. This means more buildings. Cement production continues to rise each year, which entails only more CO2 emissions.

3. Resource Damage

Cement production requires a large amount of energy use. But the smaller ingredients, like sand and stone, come from mining natural resources and habitats. It also causes a high demand for fresh water, making up about 20% of the world’s industrial water consumption.

4. Urban Heat

Both concrete and asphalt are the primary contributors to what is known as the urban heat island effect. According to the United Nations Department of Economic and Social Affairs 55% of the world’s population reside in urban areas and 68% of the world’s population is projected to be urban by 2050; also, "the world is projected to add 230 billion m2 (2.5 trillion ft2) of buildings by 2060, or an area equal to the entire current global building stock. This is the equivalent of adding an entire New York City to the planet every 34 days for the next 40 years".

These reasons show why finding alternatives to concrete must help lessen some, or all, of these consequences.

Substitutes and Alternatives

Old ConcreteFly ash Ferrocement Geopolymer Concrete Grind Granulate Blast Furnace PPC Silica Fume Photocatalytic Concrete Recycled Plastics

OLD CONCRETE

Construction waste: Unwanted materials generated during construction processes. For example: Demolished concrete fragments, Brick pieces, Wood, Plastic wastes etc.

Reuse: The process of using a material again for same or a different function. For example: Using coarse aggregate obtained from concrete waste, for preparation of fresh concrete.

Recycling: The process of converting waste materials into new ones for reduction of waste of potentially useful materials.

Why To Focus On Concrete?

• It is the most commonly used Construction material (1 ton for every man on earth)

• Aggregates are used in concrete for very specific purposes. Aggregates typically make up about 60% to 75% of the volume of a concrete mixture, and as they are the least expensive of the materials used in concrete, the economic impact is significant.

• Compared to other comparable building materials, concrete is less costly to produce and remains extremely affordable.

Demolished Concrete

• Sometimes, the concrete material has to be demolished during ongoing or old construction. The concrete waste obtained from these processes is called Demolished concrete.

• It is a very common type of waste generated during Pile foundations, pre-casting etc.

Process of reusing demolished concrete

- Collection of Construction scraps from the site.

- Classify them according to their properties.

- Send them to the Separation and Treatment plant.

- Differentiating the components i.e. the aggregates, treating them, and finally reusing them for constructing Fresh Concrete.

Process of recycling the demolished concrete

There are many processes for recycling. However, the common procedure adopted is,

• Collection of Waste from the Site.

• Transporting to the Recycle unit.

• Initial crushing and Sieving.

• Final crushing and Grinding.

• Forwarding it to the Constructing unit.

Process of recycling the demolished concrete

There are many processes for recycling. However, the common procedure adopted is,

• Collection of Waste from the Site.

• Transporting to the Recycle unit.

• Initial crushing and Sieving.

• Final crushing and Grinding.

• Forwarding it to the Constructing unit

The advantages of using recycled concrete/ aggregates are:

• Conserve diminishing natural aggregate resources

• Use of construction wastes

• Protection of environment

• Economical

• Create additional business opportunities

• Avoids excess Landfilling

Disadvantages :

However, the disadvantages and limitations are:

• Inexperience with recycled aggregate products due to lack of exposure still remain a surmountable barrier to the recycled concrete market.

• Water pollution can also happen during recycling process.

• It is still not feasible in all sites and requires heavy machinery and equipment.

Properties and Experimental verifications:

- Sieve analysis is done after crushing and sieving as per IS Code 2386 to separate out coarse and fine aggregate.

- Sp. Gravity(saturated surface dry condition) of recycled concrete aggregate(RCA) was found from 2.35 to 2.58 which is slightly

- lower than natural aggregate. • Water absorption ranges 3.05 % to 7.40 % which is slightly higher than that of natural aggregate.

- Reduction in strength of RCA as compared to NCA:

2-14 % = M-20

FLY ASH

Fly ash or flue ash, also known as pulverized fuel ash in the United Kingdom, is a coal combustion product that is composed of the particulates that are driven out of coal-fired boilers together with the flue gases. Ash that falls to the bottom of the boiler's combustion chamber is called bottom ash.

Fly ash is a byproduct from burning pulverized coal in electric power generating plants. As the fused material rises, it cools and solidifies into spherical glassy particles called fly ash. Fly ash is collected from the exhaust gases by electrostatic precipitators or bag filters.

Manufacturing of fly ash

Fly Ash Bricks are manufactured using Major percentage of fly ash generated from Thermal Power stations. Fly ash is a fine, glass-like powder recovered from coal-fired electric power generation. They consist mostly of silicon dioxide (SiO2), aluminum oxide (Al2O3) and iron oxide (Fe2O3).

Why Fly Ash ?

The main reason that fly ash is considered to be eco-friendly when used in construction is because it's a recycled material.

If power companies are going to burn coal and produce fly ash anyway, it makes sense to put it to good use, especially if it can save money and energy in the construction sector.

There are two types

1.Type F (5%Carbon)

2.Type C (2%Carbon)

Advantages

- Fly ash use in concrete improves the workability of plastic concrete

- The strength and

- durability of hardened concrete.

- Fly ash use is also cost effective.

- When fly ash is added to concrete, the amount of Portland cement.

GEOPOLYMER CONCRETE

An innovative material that is characterized by long chains networks of inorganic molecules is a potential alternative to conventional port land cement concrete.

FLY ASH + FINE AGG +COARSE AGG+ ALKALI ACTIVATORS = GPC

MATERIALS USED FOR GEOPOLYMER CONCRETE

FLY ASH - low calcium fly ash obtained from Thermal Power plant is to be used as source material.

FINE AGGREGATE - the aggregate chosen is sieved through 2.36mm and the passing material is chosen for the test.

COARSE AGGREGATE - maximum size 20mm ALKALINE ACTIVATOR SOLUTION - sodium hydroxide solution sodium hydroxide dissolved in water

BENEFITS

- Significantly lower CO2 emissions than OPC concretes – up to~90%

- Better thermal insulation properties.

- Higher temperature/fire resistance.

- Providing a viable use for 'waste' materials which are often disposed in landfill.

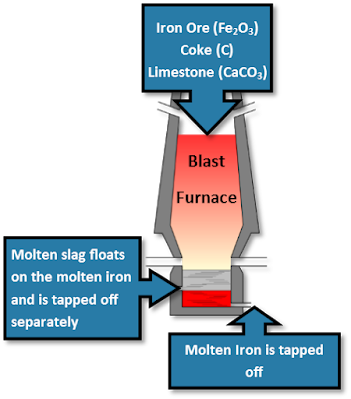

GROUND GRANULATED BLAST FURNACE

Ground-Granulated Blast-furnace Slag Sometimes, also referred to as GGBFS Obtained by quenching molten iron slag from a blast furnace in water or steam, dried and ground into a fine powder. Silicate and aluminate impurities from the ore and coke are combined in the blast furnace with a flux which lowers the viscosity of the slag.

CHEMICAL COMPOSITION

CaO 30-50% MnO 0.68%

SiO2 28-38% TiO2 0.58%

Al2O3 8-24% K2O 0.37%

MgO 1-18% N2O 0.27%

PROPORTION IN CONCRETE

Replacement levels for GGBS vary from 30% to up to 85%. Typically 40 to 50% issued in most instances.

BENEFITS

- Durability

- Appearance

- Strength

- sustainability

FERROCEMENT

Ferrocement is a construction material consisting of wire mashes and cement mortar. Applications of ferrocement in construction is Vast due to the low self weight, lack of skilled workers, no need of Framework etc.

It was developed by P.L.Nervi, an Italian architect in 1940. Quality Of ferrocement works are assured because the components are manufactured on machinery set up and execution time at work Site is less. Cost of maintenance is low. This material has come Into widespread use only in construction in the last two decades.

PROPERTIES OF FERROCEMENT:

- Highly versatile form of reinforced concrete.

- It’s a type of thin reinforced concrete construction, in which large amount of small diameter wire meshes uniformly throughout the cross section.

- Mesh may be metal or suitable material.

- Instead of concrete Portland cement mortar is used.

- Strength depends on two factors quality of sand/cement mortar mix and quantity of reinforcing material used.

CONSTITUENT MATERIAL FOR FERROCEMENT:

- Cement

- Fine aggregate

- Water

- Admixture

- Mortar mix

- Reinforcing mesh

- Skeletal steel

- Coating

ADVANTAGES OF FERROCEMENT:

- Basic raw materials are readily available in most countries.

- Fabricated into any desired shape.

- Low construction material cost.

- Better resistance against earthquake.

DISADVANAGES OF FERROCEMENT:

- Structures made of it can be punctured by collision with pointed objects.

- Corrosion of the reinforcing materials due to the incomplete coverage of metal by mortar.

- It is difficult to fasten Ferrocement with bolts, screws, welding and nail etc.

- Large no of labours required.

- Cost of semi-skilled and unskilled labors is high.

- Typing rods and mesh together is especially tedious and time consuming.

PROCESS OF FERROCEMENT CONSTRUCTION:- Fabricating the skeletal framing system.

- Applying rods and meshes.

- Plastering.

- curing.

APPLICATION OF FERROCEMENT IN CONSTRUCTION:- Housing

- Marine

- Agriculture

- Anticorrosive membrane treatment.

- Rural energy

- Miscellaneous

SILICA FUME

- Silica fume is a byproduct of producing silicon metal or ferrosilicon alloys. One of the most beneficial uses for silica fume is in concrete.

- Because of its chemical and physical properties, it is a very reactive pozzolan. Concrete containing silica fume can have very high strength and can be very durable.

- Silica fume is a by-product from the production of elemental silicon or alloys containing silicon in electric arc furnaces. At a temperature of approximately 2000°C the reduction of high-purity quartz to silicon produces silicon dioxide vapor, which oxidizes and condenses at low temperatures to produce silica fume.

- The durability of this type of concrete fend off most aggressive chemical attacks.

PHOTOCATALYTIC CONCRETE- Photocatalytic concrete is a type of environmental friendly material, by which air pollution or pollution on the concrete surface can be diminished. It can catalyze chemical reaction with the involvement of light illumination.

- It decomposes most of the gases that emits from car exhaust and those produced because of emitted gases with rainwater.

- Tio2 is a catalytic material, which activated using sunlight. When it activate, separation of electron spread over the surface and decompose organic compounds.

CONSTRUCTION AS AN EXPANDING AND SUSTAINABLE, INDUSTRY

1.“Green” building designs have made their mark on the construction industry recently, thanks to a desire for homes and commercial buildings that are more energy-efficient. Benefits from this efficiency include lower monthly energy costs and the reduction of carbon footprints.

2.Many construction companies have led the way on sustainability – in fact, 9 out of 10 architects consider sustainability a priority when choosing project products and materials.

3.When it comes to selecting materials, workers are looking outside the box to make smarter choices for their construction sights. Factors such as efficiency, durability and savings are all taken into consideration.

RECYCLED PLASTICS DIRECTLY BENEFIT THE CONSTRUCTION INDUSTRY

1.When recycled plastic is blended with virgin plastic, costs can be lowered because there is a lower amount of brand-new plastic being used and produced. Using recycled plastic can also help save on the costs of other materials, such as wood and slate.

2.As a low-cost alternative to other materials, this type of plastic being salvaged has brought new life to many industries and companies across the U.S. and around the world. Below, we’ll dive into more specific examples of how using recycled plastics has changed the way a number of materials are being produced.

1.Recycled plastics can be used to make stronger concrete structures in the form of sidewalks, driveways and more. Students at MIT have recently conducted experiments with recycled plastic by exposing small amounts of it to gamma radiation, mixing it into a powder and then mixing that into cement paste.

2.Doing so can produce concrete that is up to 15% stronger than regular concrete, allowing this form of construction to be both longer-lasting and more eco-friendly.

Green Living, Not Just Green Building

-----------------------------------------------------------------------

or reload the browserDisable in this text fieldEditEdit in GingerEdit in GingerEnable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldEditEdit in GingerEdit in Ginger

or reload the browserDisable in this text fieldEditEdit in GingerEdit in GingerEnable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldEditEdit in GingerEdit in GingerEnable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldEditEdit in GingerEdit in GingerEnable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldEditEdit in GingerEdit in Ginger

Comments

Post a Comment